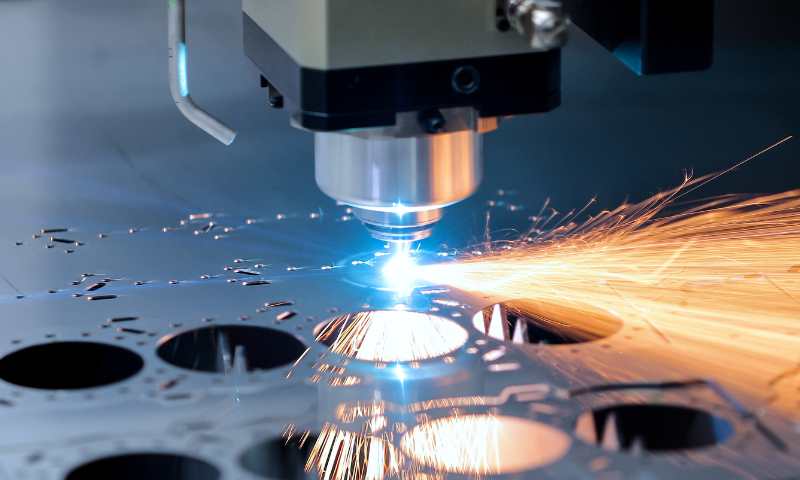

What You Should Know Before Using a Laser Marking Machine

Are you about to operate a laser marking system for the first time? Before you do, check out our brief guide of what you should know before using a laser marking machine, from laser settings to safety precautions, below!

The Machine Parameters

Before you begin laser marking, you should familiarize yourself with the machine and its settings. The first step to understanding the machine is understanding what the laser marking parameters mean.

Laser marking parameters adjust the speed, power, pulses per inch, frequency settings, and more. These parameters will affect the laser mark’s depth, clarity, and precision and will vary depending on the material’s hardness and the detail of the engraving or marking.

The Machine Software

Another thing you should know before using a laser marking machine is its software. The software of the laser marking system allows operators to create and import their designs from their personal computer or laptop to the control computer of the machine.

Obviously, you’ll want compatible software with your laser marking machine, so ensure your computer’s software is compatible with your system. Some laser marking machines come with free software and offer features like automatically adjusting the laser parameters based on the identified material.

Ventilation Is Critical

An important safety consideration for any laser marking system operator is ventilation. Whether you’re marking material in a home workshop, in an industrial workplace, or somewhere else, you always want to ensure quality ventilation.

The laser marking system will vaporize materials, which produces airborne debris like smoke and soot. If you spend too much time in this area without proper ventilation, you can breathe in this harmful debris. The laser marking system will come with ducting, which you should connect to an exhaust vent outdoors. Alternatively, you can use a fume extractor.

Always Wear PPE

Lastly, safety always comes first, including personal protective equipment (PPE). While laser marking is a relatively safe procedure, it can still damage an operator’s eyes or skin if directly or indirectly contacted. So they should always wear protective clothing and goggles during operation.

Safety Note: Never look directly into the laser beam while engraving or marking—it could result in permanent eye damage even with protective eyewear.

Flame-resistant clothing is ideal for protecting the skin from potential burns caused by reflecting lasers, and protective eyewear guards the eyes from scattered light. Certain goggles are best for certain lasers like CO2, fiber, and UV lasers, so find the recommended eye protection for your specific system.

Would you like to receive similar articles by email?