What’s Next For 3D Printers?

A new industrial revolution is on the way. The technology that is driving the latest reformation in manufacturing processes is 3D Printing. 3D printers turn computer models directly into physical things in a process that seems almost magical. At the time of the publication of this post, the whole of the news media is agog at the discovery that private citizens are using home 3D printers to create functioning plastic handguns. The media’s succession of 3D gun stories has touched off a brisk ethical debate, but all of them ignore the fact that people have been fabricating their own homemade firearms for generations. The only thing new about the issue is this emerging technology.

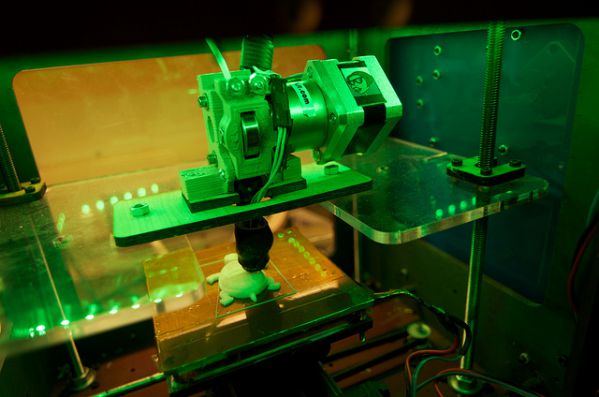

Printing sold objects from a computer rendering may seem supernatural and otherworldly at first, but in truth, the process is not much different from the action of printing a standard text document with an ink jet printer. The primary difference being the “ink” used to print the object. The process of 3D printing replaces ink with a slender filament of molten liquid plastic. In this process, a print-head deposits thin, successive filament layers a fraction of a millimeter in thickness, and one layer at a time until the finished product emerges.

3D printing is an additive process that creates objects by building up a great many layers of thin material over several hours. A simple plastic toy the size of a deck of cards can take all day to produce. 3D printing works better for prototyping rather than actual manufacturing, but recent advances in materials technology is changing all of this. One creative inventor has developed a wood-based filament suitable for most commercial 3D printers. Printing with this material creates finished objects that look, feel, and even smell like real wood. Other emerging developments in 3D printing technology are changing the metals manufacturing process. A new way of forging metal products called “sandcasting” has sped up the production cycle of metal objects. It involves spraying a liquid binder onto common sand. When hardened, the printed object acts as a mold for casting. In the next step, molten metal flows into the mold, and when cooled, the sand can be easily broken away revealing a shiny new finished product.

The future of 3D printing technology is an exciting one. At this moment, bioengineers are busy concocting ways of using 3D printers to create new “bioprinted” body parts. This concept calls for the output of actual living cells in such small quantities that they can be deposited exactly where needed. Just as in 3D plastics printing, layers of living cellular tissue are grafted together over a period of time to create an organic object. Further advances in this class of technology may soon produce the very first manufactured organs suitable for human transplant.

One area of 3D printing science that intrigues every futurist is the prospect of printing food. In fact, the world’s first 3D chocolate printer is now on the market. Some scientists now speculate that the development of a full-scale food synthesizer is a realistic objective. Instead of plastic filament or adhesive binders, food printers of the future will create edible products one thin layer at a time from powders, liquids, and strands of soy based ingredients cooked by means laser light. Incredible as it may seem, food may very well be the new frontier for 3D printing technology. Having perfected the process of printing out chocolate treats, the next great challenge of food-printing engineers will surely involve creating perfect bowls of pasta and breakfast cereals.

3D printer photo by Keith Kissel. License: CC BY 2.0.

Would you like to receive similar articles by email?